- MadreMax®

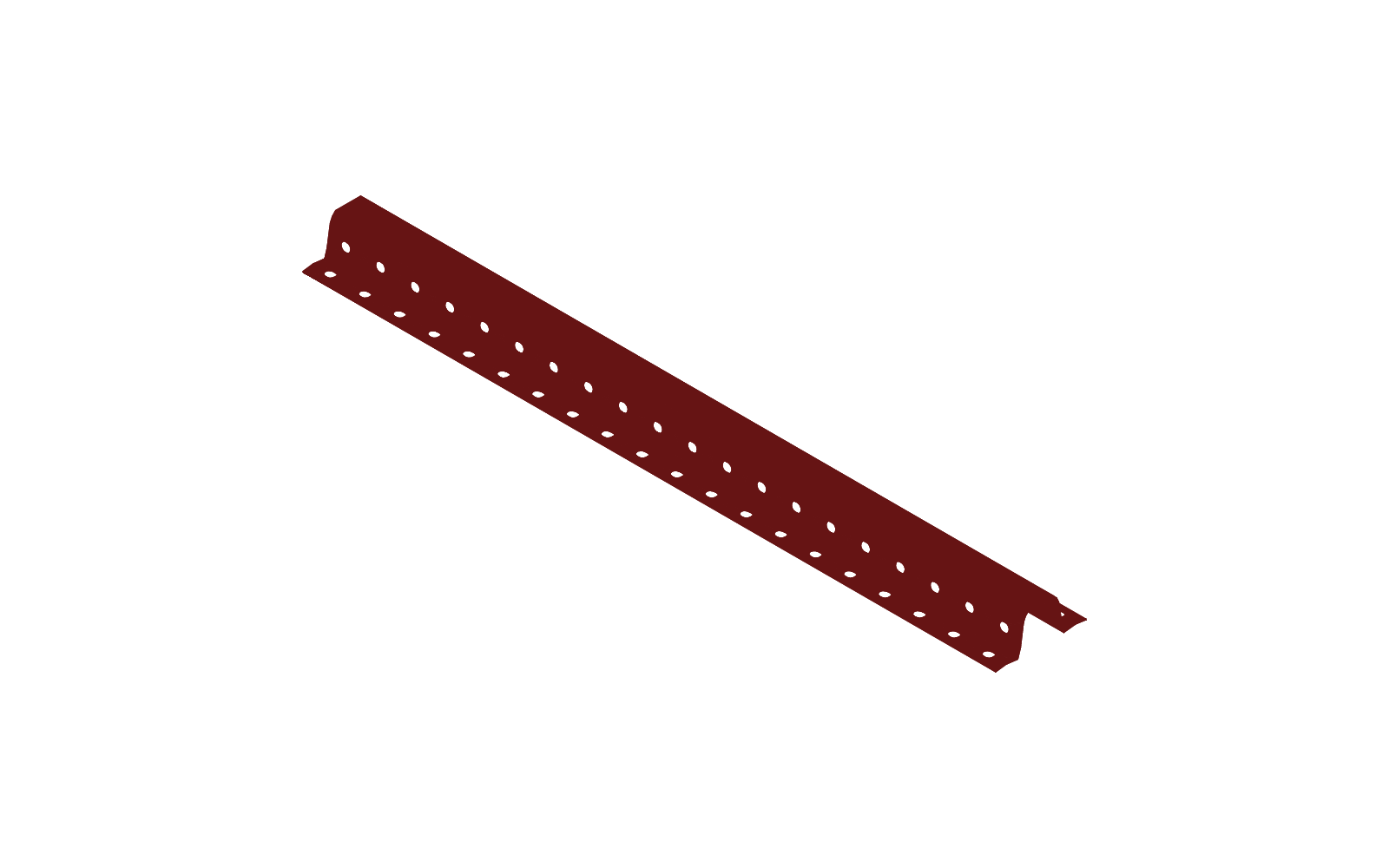

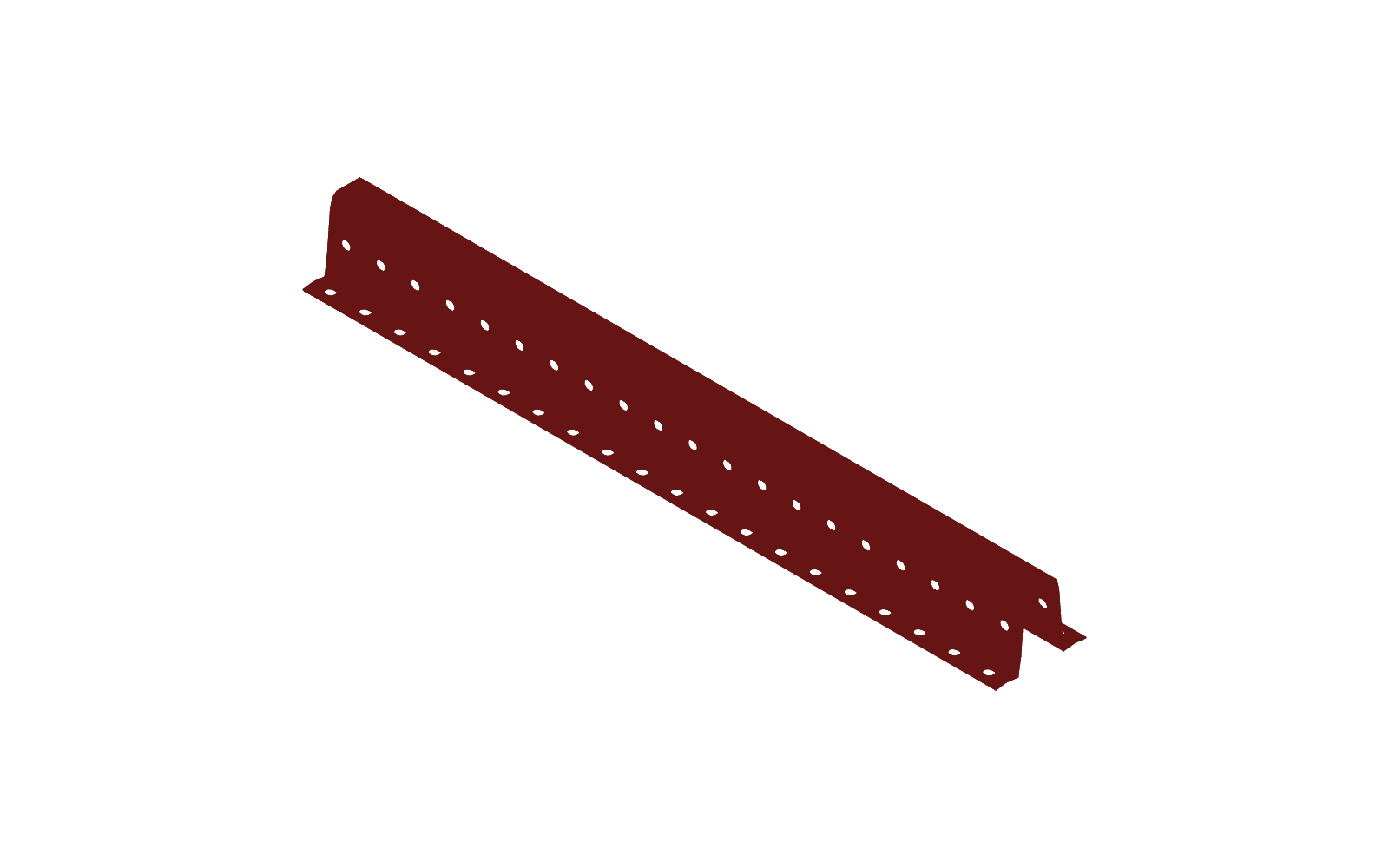

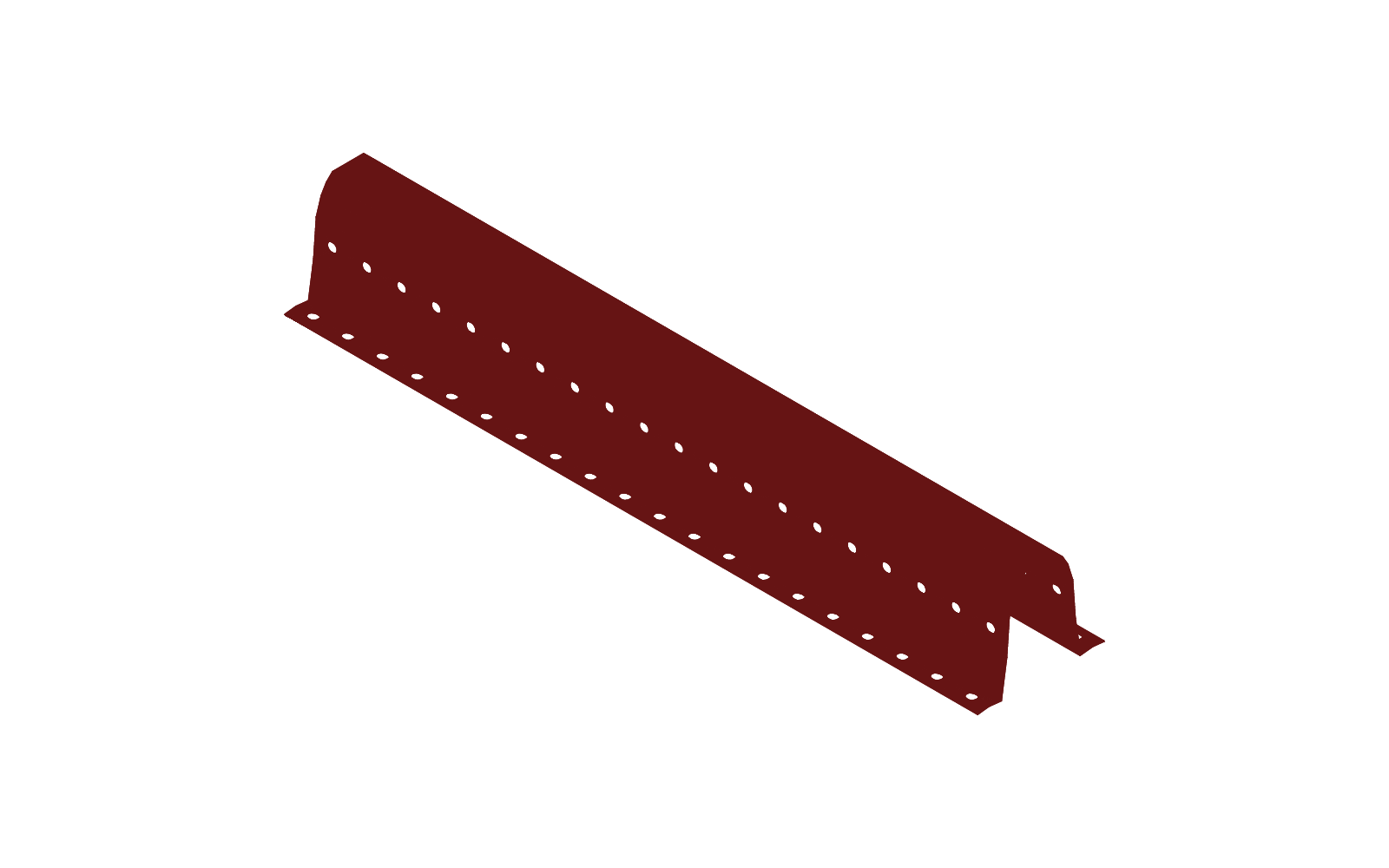

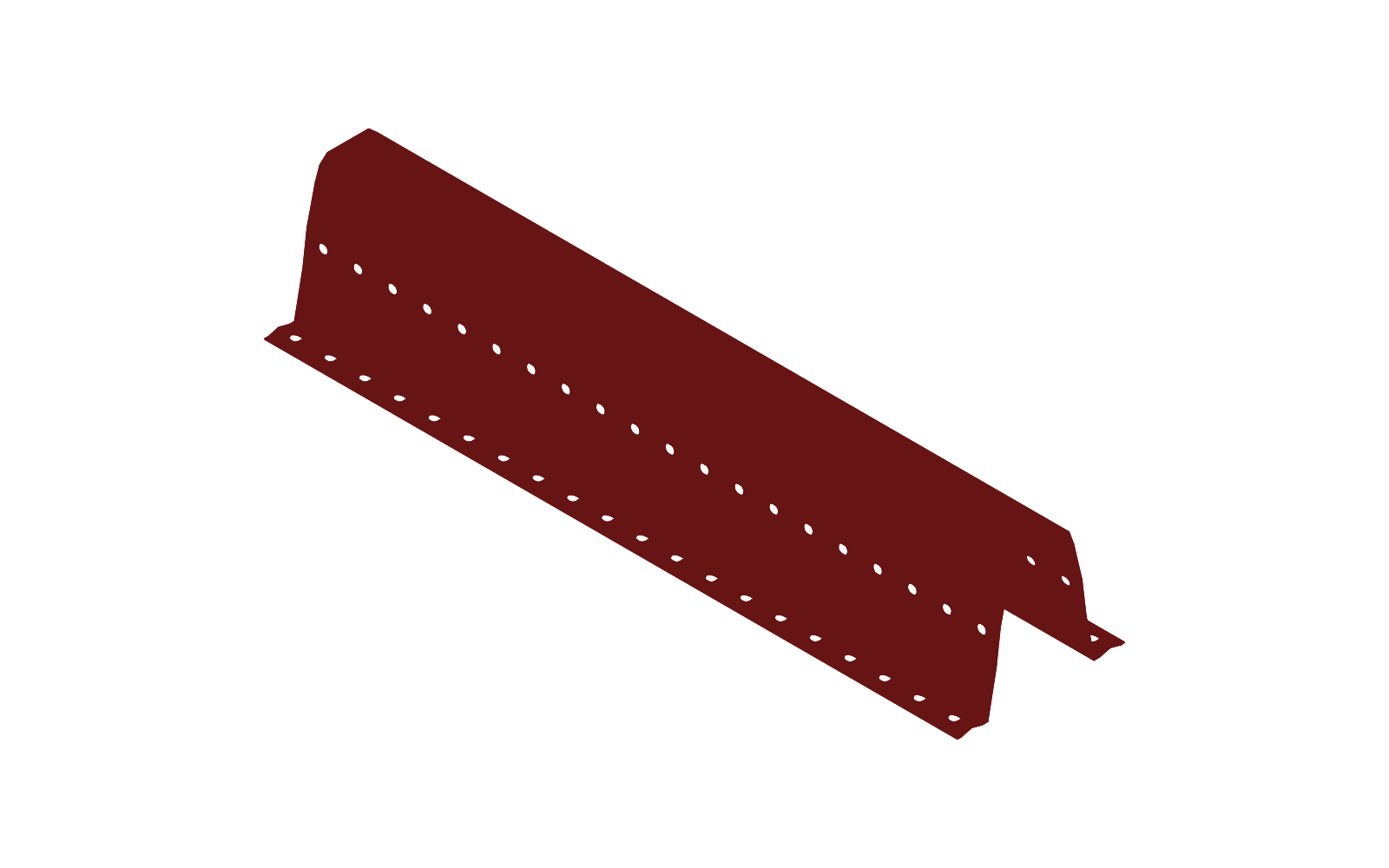

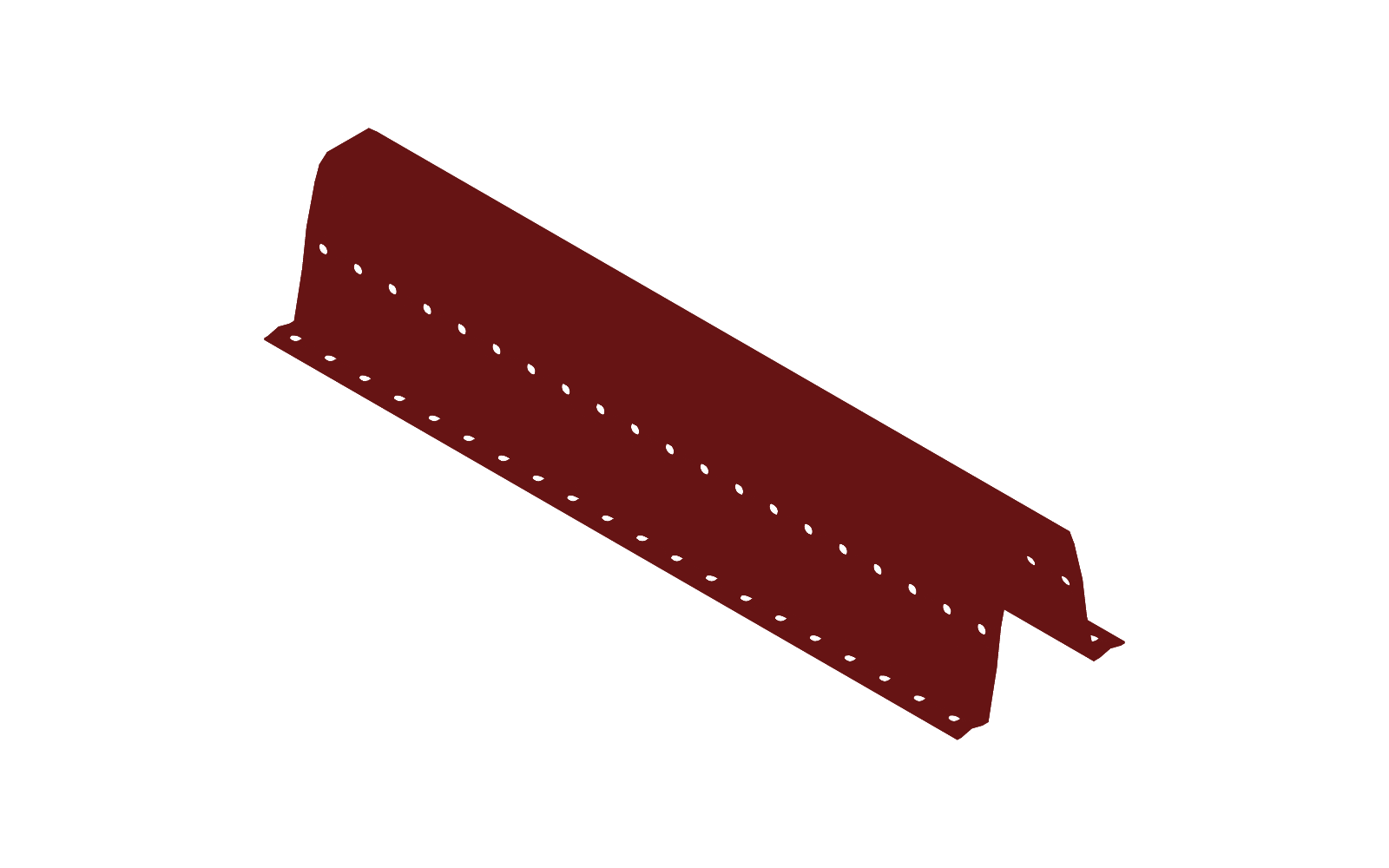

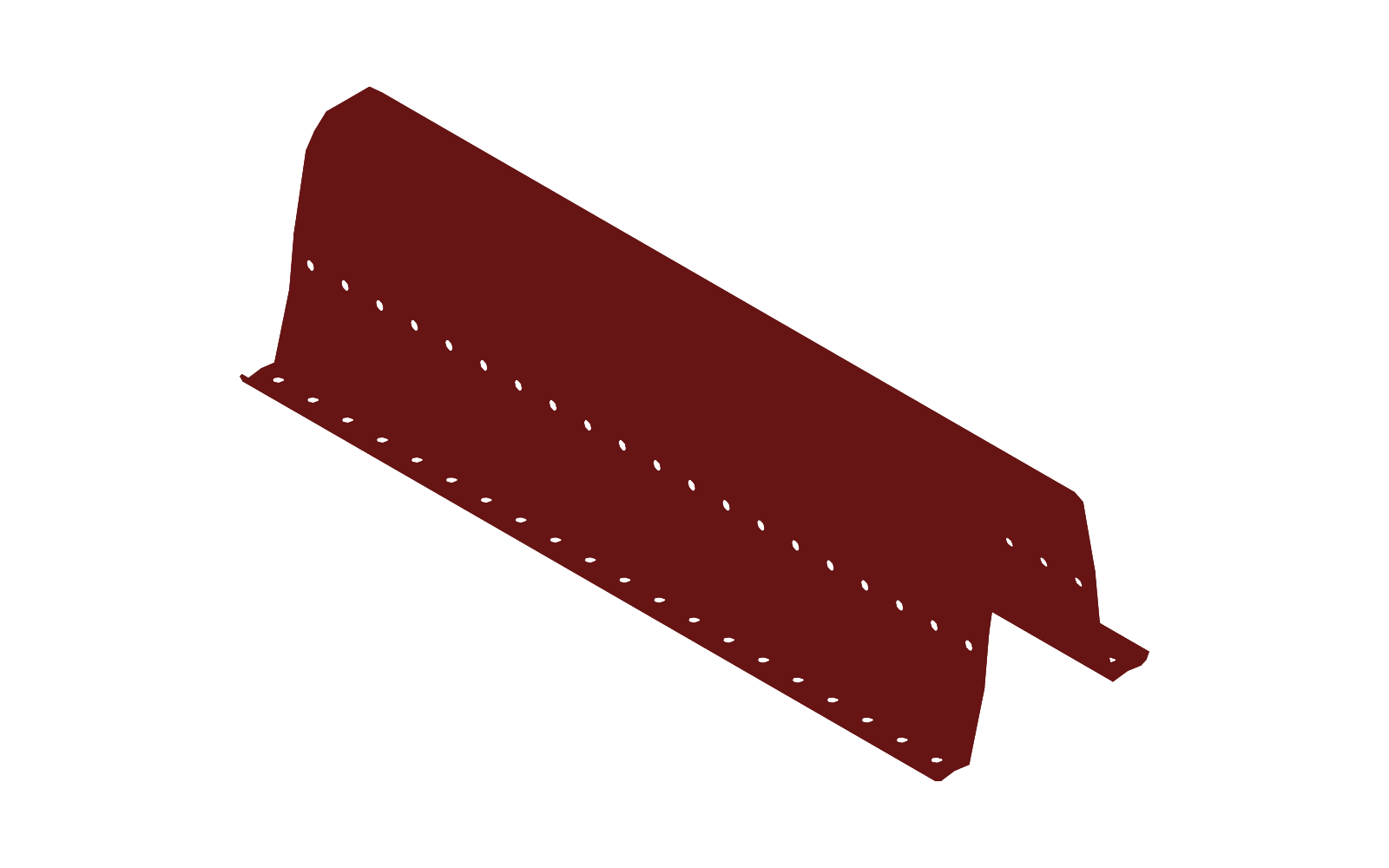

- MaxBox

Menu

less raw material and labor / faster assembly

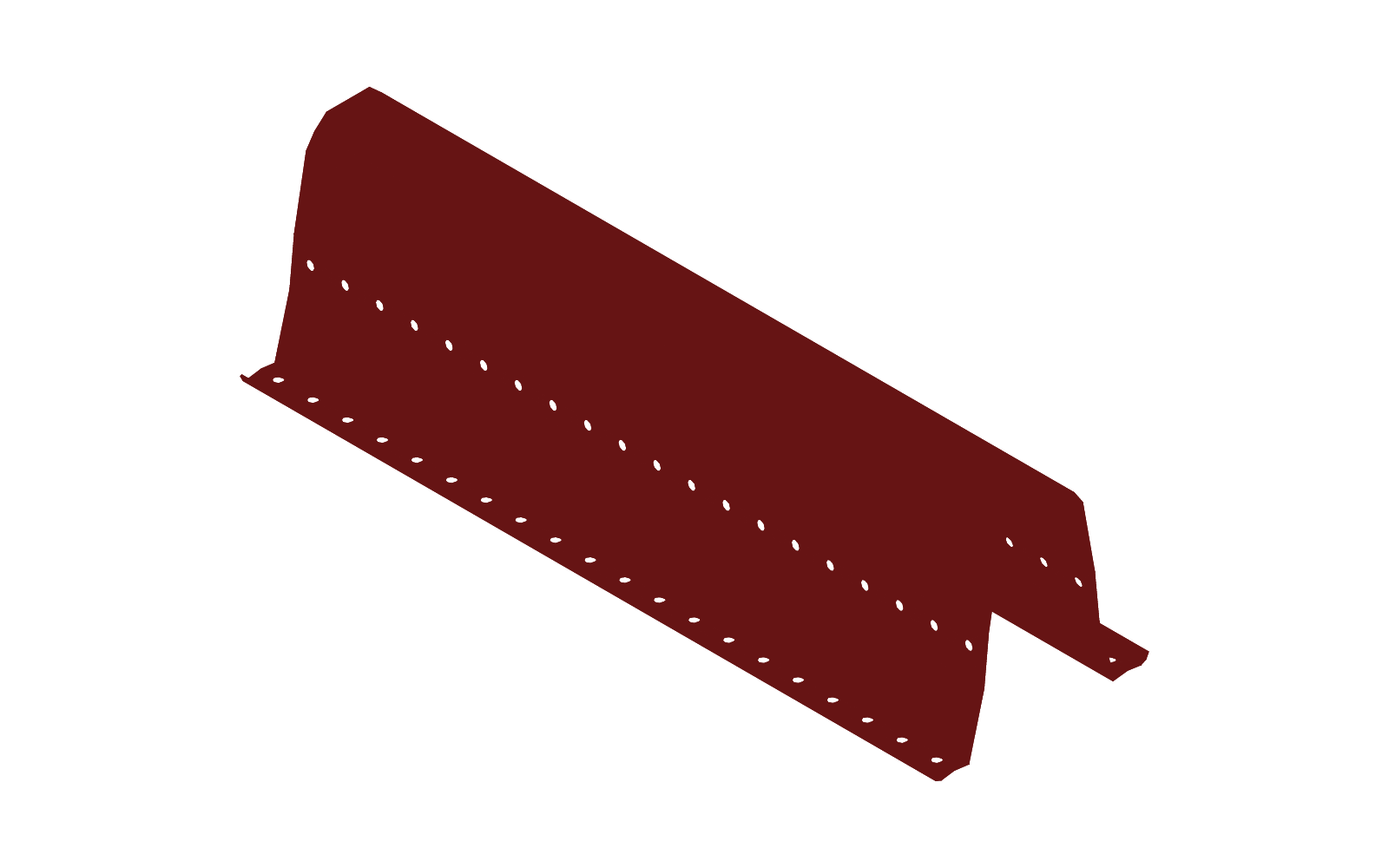

Coverage and Facades

Cartaxo . Portugal . 2019

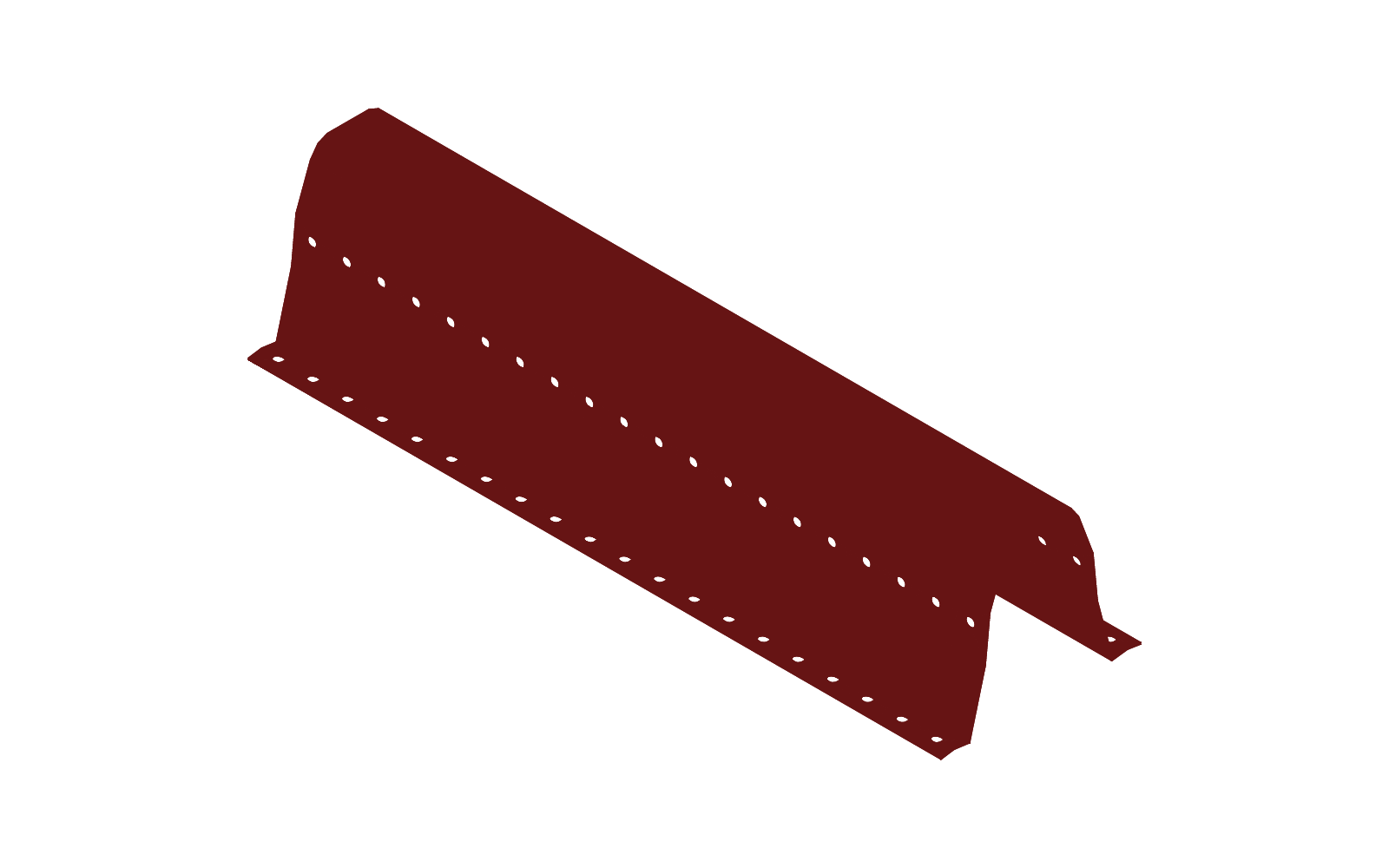

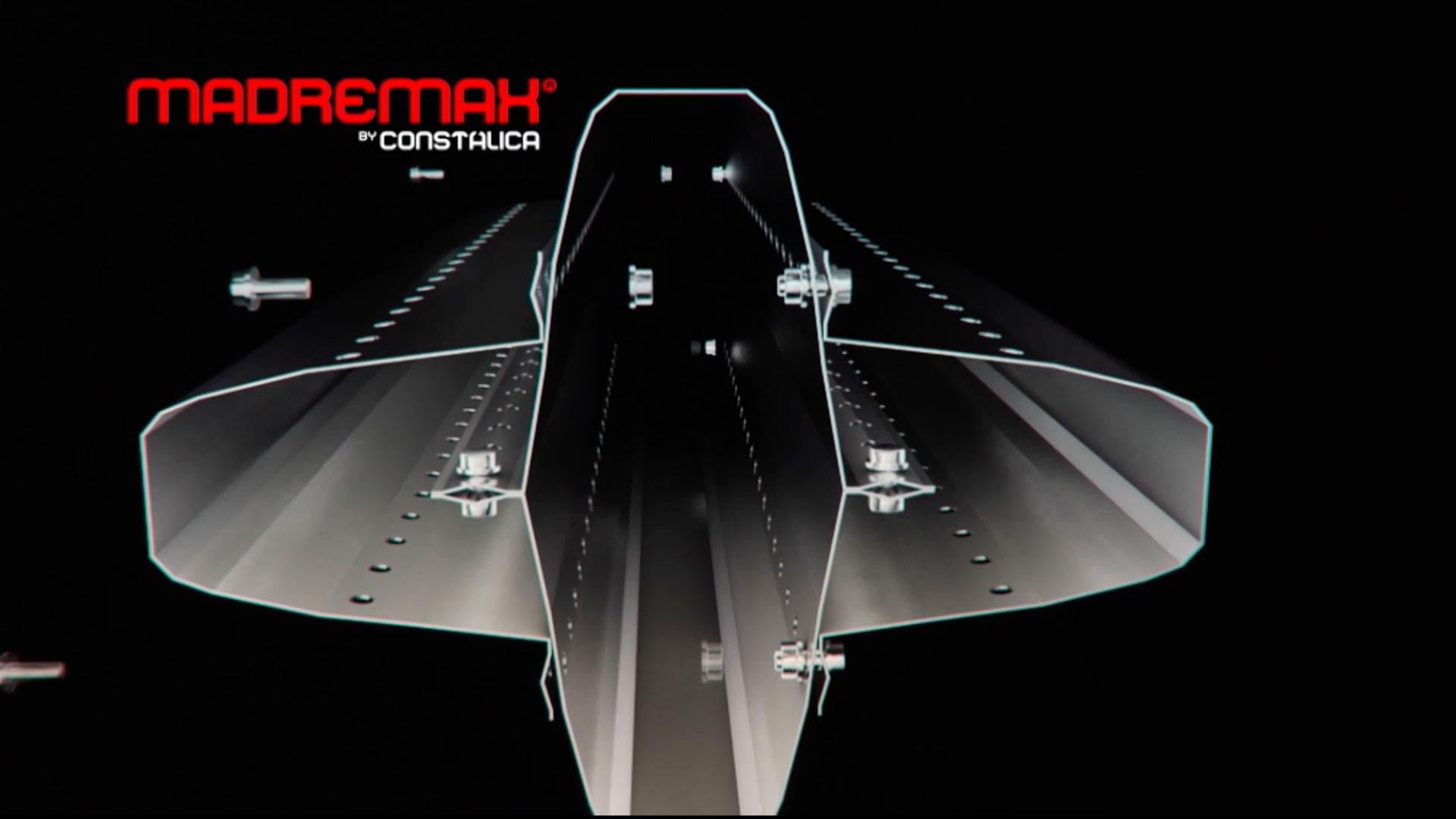

The idea from the MadreMax® system emerged from the goal of developing a product that integrated less raw material and labour, allowing a higher speed of assembly and avoiding the difficulties.

*labelFeatures

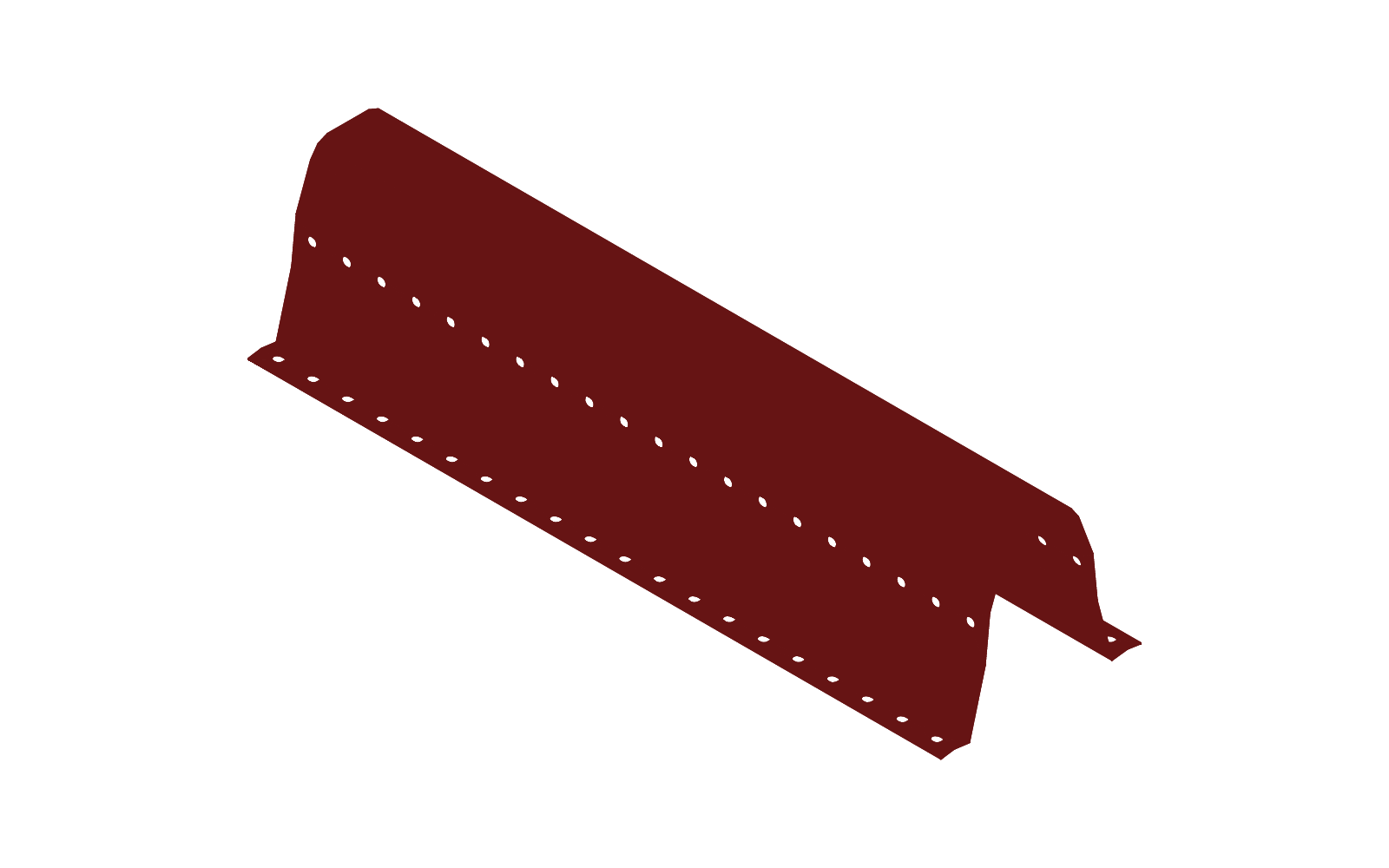

this system is marketed in 9 cross sections

Ω50

x1.5

The raw material used for production of MadreMax® is galvanised structural steel S350gd + z275 (en 10346)

the structures of the future

advantages by Developing a product that integrated less raw material and labour, allowing a higher speed of assembly and avoiding the difficulties.

know more about madremax

- Flexibility of solutions

- Structural lightening

- Direct bolting to pillars and trusses

- Savings in material, labour, manufacture and assembly

- Fast assembly

- With MadreMax® it is no longer necessary to use: tie-rods between purlins; struts; reinforced beams (trusses in façades); interior ridge plates.

- Continuous beam model

- Possibility of spanning large spans and allow greater spacing between purlins.

*labelApplications

This system has many applications, such as covering and façade purlins, for any type of revetment and superstructure in steel, wood or concrete.

This system is also in the origin of other solutions, resulting from the innovation efforts made by Constálica. The company has been developing its concept for integrated and completely produced solutions according to the MadreMax® concept. This way, the company has developed industrial structures, residential structures, photovoltaic structures and other structures entirely built with the MadreMax® system.

*labelNextProduct

*labelKnowProduct

null

null